Dearman Systems ‘poised for growth’ over the next decade

Founded in 1988, Dearman Systems has grown into a major player in the terminal automation space over the past 30 years. From its birthplace in sunny Tucson, Arizona, Dearman has now expanded to serve nearly 200 unique customers and nearly 300 terminals worldwide.

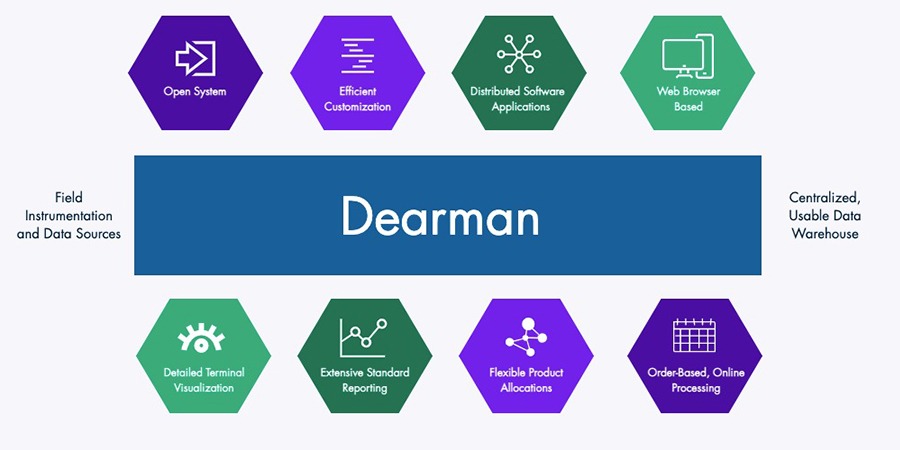

Dearman’s core software solution automates certain manual processes in a terminal, specifically around load authorisation, product movement (via multiple transportation methods), product measurement, documentation, and reporting.

The software is flexible and open to integration with other siloed systems and hardware, including meter skids, weight scales, tank gauging systems, and secure access control systems.

Dearman currently handles a wide variety of terminals including bulk petroleum, chemical, renewable fuels, aviation, liquified natural gas (LNG) and liquified petroleum gas (LPG) terminals.

Flexible product offerings

Dearman offers two implementations of its terminal automation system: RTG (Ready-To-Go Terminal Automation) and TAS.net. With over 25 pre-built connectors to popular field devices, Dearman integrates your operations utilising robust process control to deliver the level of automation required.

Specifically, process control is the proprietary logic that enables operators to communicate with and control field instrumentation and devices in an orchestrated manner and utilise data from these devices for practical business functions.

RTG: Typically used by small to medium sized operations, RTG is designed to be remotely installed and comes in standard communication configurations (2-port or 4-port) depending on the number of devices you need to control. RTGs can be installed quickly, virtually right out of the box.

TAS.net: Highly scalable and customisable, TAS.net can connect to an unlimited number of instruments to fully integrate your terminal operations across all transportation methods including truck, rail, barge, and pipeline.

Both RTG and TAS.net support bottom and top loading of trucks, rail car loading and unloading, weigh scales, volume and mass metering, and manual loading. Communication with most automated tank gauging systems for real-time graphical display of product levels and volumes is standard functionality as is the emailing of BOLs and reports to any number of recipients.

RTG and TAS.net are based on the Microsoft.Net® framework and Component Object Model (COM) and can be accessed securely from remote locations using only a web-browser. The platform not only makes simple and secure remote management of terminals possible, it also makes customer self-scheduling and order management a reality.

Through its Terminal Graphics Builder module, Dearman enables customers to take complete control of their terminal’s process management functions and monitor product movement in real-time.

Users can see terminal overview graphics, specific loading or unloading bay activity, and current product storage location information.

UNITY: Dearman also offers an Enterprise Management solution called UNITY which unifies data between multiple terminals. UNITY provides a single view into your entire operation and allows you to share data between a central office and any number of terminals in real-time.

Additionally, UNITY is commonly used as a data warehouse and provides redundancy should an on-site server go down.

Dearman believes in providing terminal automation systems that fit customers’ needs at the terminal level and across their enterprise. Dearman offers a range of optional modules that drive value for different functions across organisations, including:

– Accounting Interface

– Contracts & Invoicing

– Inventory Management

– Scheduling & Customer Orders

– Enterprise Reporting

– ExSTARS Reporting

– RIN Management & EPA Compliance Reporting

Dearman says it employs a highly technical sales staff which takes the time to understand its customers’ needs and recommends solutions based on their operations: “Your organisation’s particular needs determine which applications you buy and use — empowering your decision makers to get the critical answers they need.”

Product Philosophy

Dearman Systems was founded by Les Dearman, who remains a valuable technical consultant to the company. He is known as a thought leader in terminal automation technology and has created meaningful relationships with many of the major bulk liquid storage companies by providing reliable and highly-secure products as well as consistent high-quality customer support.

Les Dearman’s product philosophy, which continues to permeate Dearman, is that terminals’ needs vary and therefore systems need to be adaptable. Dearman does not impose any terminalling hardware requirements on clients.

Instead, it consults with them on what is best for their needs and budget from the myriad of great products on the market: “The many hardware and software systems available demand that an automation and enterprise management package be flexible enough to simultaneously mingle the latest products with those already installed.”

Ultimately, Dearman’s strategy is to offer a complete set of software components which function properly whether in a stand-alone setting, or integrated across an enterprise – all while maintaining a low cost and high performance product.

Looking forward

This year, Dearman is upgrading its core terminal automation software to enhance security and usability. Dearman is also launching two new, upgraded modules: enhanced enterprise reporting and self-service scheduling, that will be revolutionary within the industry. Additionally, the company recently opened a Houston office and has an aggressive expansion plan which includes opening offices in South America, Southeast Asia, and Northern Europe to support new business on a global-scale.

For more information visit www.dearmansystems.com

25th February 2021